- English

- 한국어

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

- Español

Good mask machine: What standards should it have?

Desheng is a professional mask machine manufacturer. Not all mask machine manufacturers have the same capabilities.

We have extensive experience in manufacturing automated testing equipment.

We can customize automated equipment based on our customers' needs and requirements.

We are committed to quality, providing superior automation solutions and high-level service to customers worldwide.

Medical Mask Machine Safety Certification

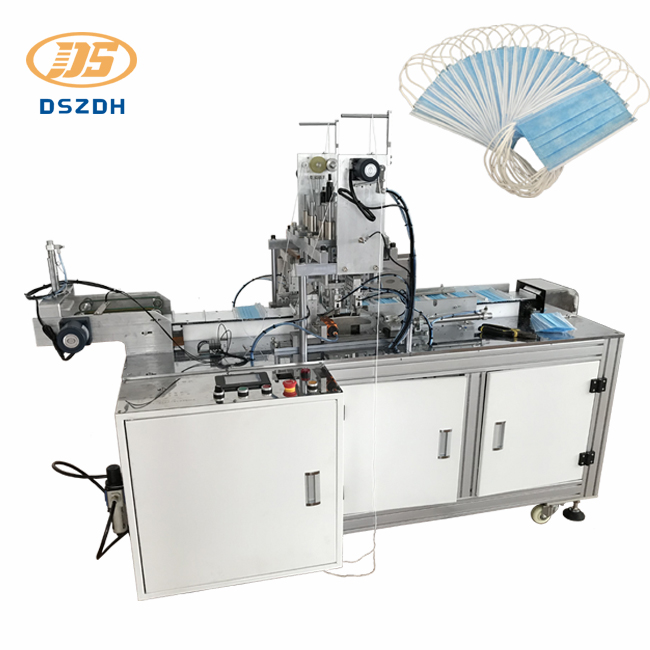

Mask machines, also known as mask manufacturing machines or mask production lines, have mechanical and electrical equipment that significantly impacts the safety and reliability of mask production.

Generally speaking, the most common hazards associated with mask machines are as follows:

Physical hazards during normal operation, such as mechanical damage, electric shock, radiation, and noise, can pose risks to operators and compromise the integrity of the equipment.

Shortened contact life due to excessive component damage, electrical effects, and other factors. For example, according to the EU CE certification and Machinery Safety Directive MD 2006/42/EC, masks must comply with ISO 12100 EN 60204-1 standards to effectively protect against these hazards.

Medical Precautions

Before installing, using, maintaining, and repairing a medical mask machine, please read this manual and all other accessories to ensure proper use.

The operator must be qualified to operate the machine. Masks must meet the following requirements: they must not contain corrosive substances, fumes, chemical deposits, dust, or other contaminants that could seriously affect the machine's operation. Masks are flammable and explosive. If you feel unwell, please return the machine.

It is worth noting that CE certification is a hallmark of safety and quality for medical mask machines.

Troubleshooting

A medical mask machine consists of four main components: a feeder, a mask making machine, an ear loop welding machine, and a mask packaging machine. Troubleshooting a medical mask machine involves adjusting these four components to ensure that the non-woven fabric, nose pads, and ear loops are assembled in a specific order and structure to ensure the correct mask size and stable production.

Mask production is the most critical process, focusing on the correct folding and alignment of the masks.

In the automated mask packaging process, the difficulty of welding lies in ensuring accurate weld positioning, stable welding, and smooth folding.

Mask Machine

The mask machine unit is designed to ensure continuous and stable production. Mask production is non-standard automated equipment, and its components are not yet modularized and standardized. Therefore, to ensure successful commissioning within a certain timeframe, the following commissioning procedures are the best approach.

Drama series about medical mask machines primarily focus on the following stories:

For example, films such as "The Grand Passage," "Earrings Fall Off Easily," and "The Huge Advantage of Independent Research and Development." In addition to the impact of commissioning on the machine, component performance is also a significant factor in the problems and difficulties encountered with these mask machines.

Each mask machine undergoes multiple tests, using raw material weighing three times the nominal value to ensure proper startup under high loads and minimize component damage.

Each machine undergoes rigorous testing with specialized instruments to measure essential parameters such as frequency, resistance, and capacitance.

The steel molds are made of D2 steel imported from the United States, and our company employs advanced heat treatment processes to achieve the highest quality standards. Parameters such as frequency and current are rigorously tested and controlled.

Combined Ultrasonic Aging Test:

Aging Test Standards

Long-wave Method: Test Time > 12 Hours, Temperature < 50°C

Short-wave Method: Test Time > 12 Hours, Temperature < 40°C

The ultrasonic system for medical masks consists of an ultrasonic generator (ultrasonic generator), an ultrasonic power supply, and a frequency conversion system.

This ultrasonic system is the primary welding component of a medical mask machine, used to weld the perimeter, nose bridge, and ear flaps of the mask. It is the core component of the mask machine.

| Component | Specifications | Features |

|---|---|---|

| Mask Designing System | Customizable templates, multiple patterns incorporated | Supports batch production, ensures precise matching, improves workflow efficiency |

| abei fitment | High-precision cutting, automatic quality inspection | Reduces manual intervention, ensures consistent product quality, enhances operational efficiency |

| Feeding and Pressing | Automatic feeding with variable speed adjustment | Ensures smooth and rapid material feeding, optimizes materials utilization |

| Mask Sealing | Heat-sealing technology, customizable seal modes | Precise temperature control, low power consumption, effective energy management |

| Maskuffing | Uniform puffing process | Generates fine particle distribution, improves mask comfort and fit, optimizes mask structure |

| Guests' Drawing | Auto-power supply, environmentally friendly | Energy-efficient solution, optimized power utilization, maintain constant air pressure |

| Wastewater Processing | Advanced filtration technology | Stable and efficient wastewater treatment, reducing environmental pollution |

| Dust Collecting System | Effective dust removal | Complete filtration, enhanced environmental protection, reduces product loss in collection |

| osen Control System | Intelligent control, real-time monitoring | Stable operation, easy maintenance, saving time and reducing costs |

| Date marking method | Plain Sticker, Coated Sticker | Achieves precise marking, no need for resetting, saving time and improving production efficiency |

| Automatic Safety Lock Down | Fault monitoring, automatic shutdown | Sealed power supply, eliminating human errors, improving product safety |

Only professional technology and qualified spare parts can ensure the machine's excellent performance.